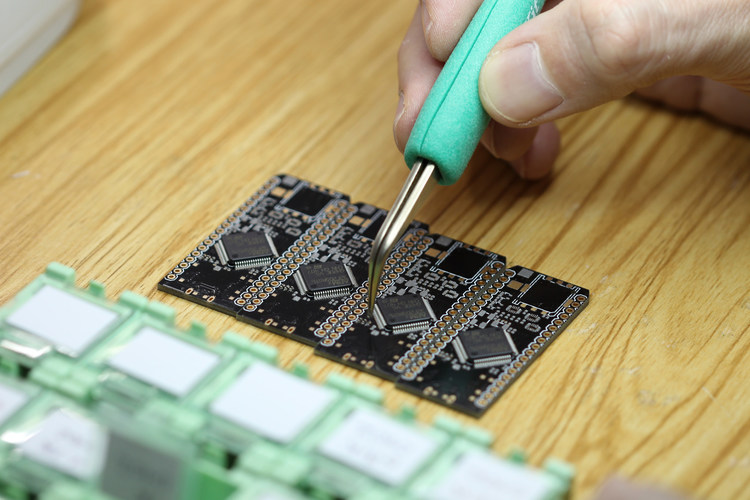

The printed circuit board (PCB) prototype assembly is almost identical to the full run PCB Assembly, with the largest difference in the number of PCBs in use. Many parts generate heat in the PCB, so the inventor must listen to the manufacturer’s instructions about the spacing part of an assembly PCB prototype. Most PCBs are made to fulfill a specific task and optimizing the PCB for the task can amplify the prototype. When doing PCB Prototype assembly, it is usually best to leave the space around the edge for security reasons. Some of the insides of the PCB should be placed in a certain area, and it can be easier to put this first part.

While PCB Prototype is one that is not in the market, there are usually many commercially available parts used to assemble a PCB prototype. Many of the parts are equipped with PCB Manufacturing instructions showing how far away from each other parts should be placed to ensure that the heat generated by each piece does not damage near the component. It is usually best to follow this as long as the PCB Prototype assembly; Otherwise, the Board may have a very short lifespan.

Selecting parts for the PCB Prototype assembly should be done based on the needs and functions to ensure the PCB is optimized for the task it is intended to perform. For example, if a PCB is meant to increase processing speed, then using components that best integrate with a central processing unit (CPU) should be selected. This will help the PCB work properly, and often make the task of taking part easier. You should visit this China PCB Assembly.

The inventor is able to fill in the PCB area for edges with components, but this can be a bad idea. During the Prototype PCB assembly, the inventor must leave the border about 2.5 millimeters free from each part. If there are components near the edge, then they are less resistant to heat, and any shock to the edge of the PCB can physically damage the component and damage the PCB.

Parts used in PCB Prototype assembly can be placed anywhere, but there are some that need to be placed in a certain place. Although not necessary, it’s usually easier to put this first part. This makes it easier to plan where other parts go and ensure that these parts get their special places before other parts fill the zone.